Closeouts

224 Results

38023

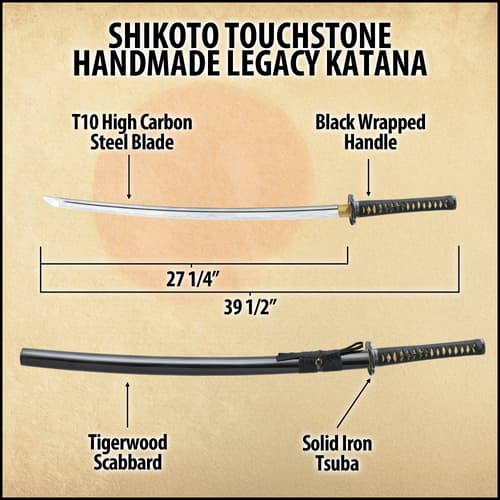

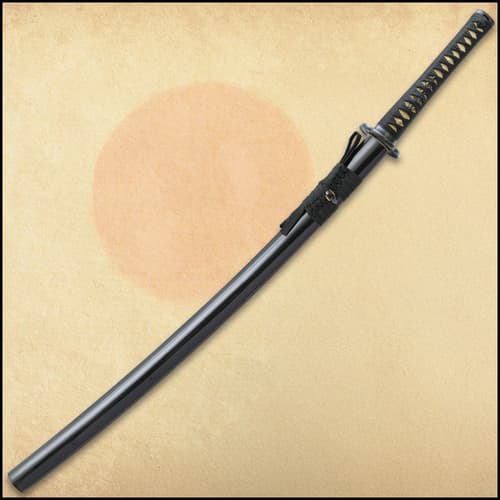

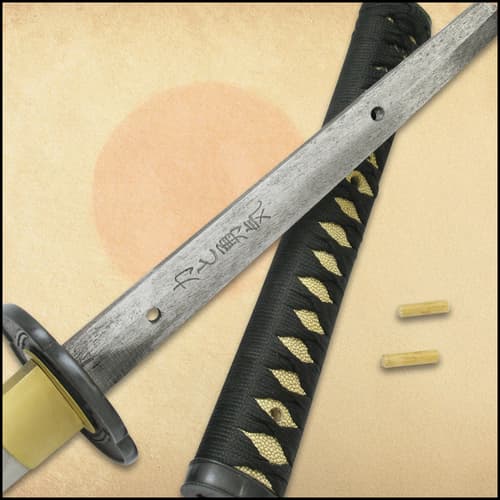

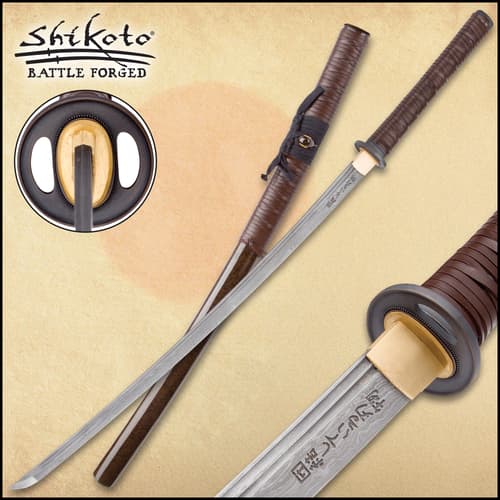

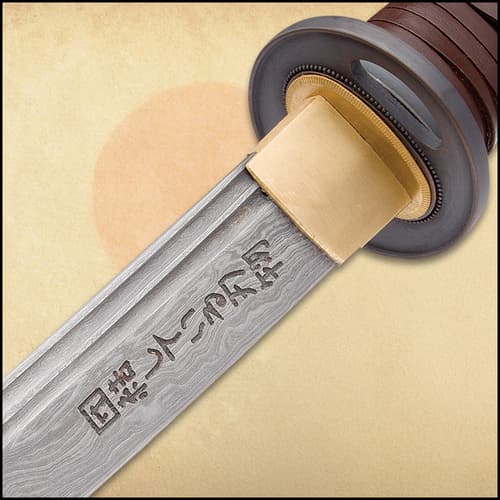

Shikoto Touchstone Handmade Legacy Katana / Samurai Sword

USD

3

Shikoto

Swords

Japanese Swords

T10 Steel Swords

CL1

Category L1

369.99